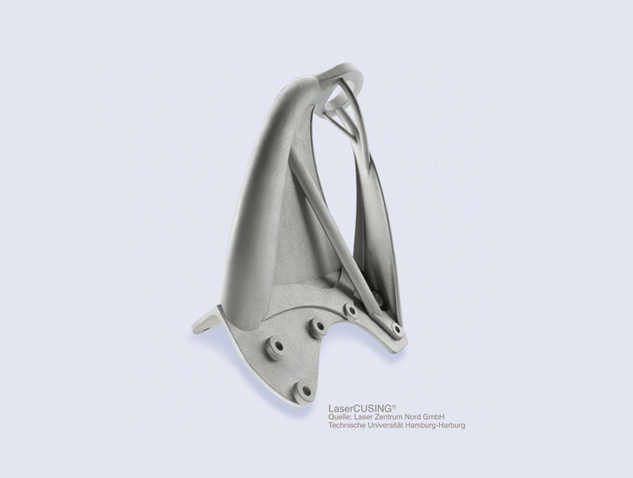

M2 cusing Multilaser TECHNICAL DATA

Build envelope LaserCUSING® 250 x 250 x 280 mm3 (x, y, z)

Layer thickness LaserCUSING® 20 – 80 μm

Production speed LaserCUSING® 2 – 35 cm3/h (depending on material / laser power)

Laser system 2 x 200 W (cw), optional 2 x 400 W (cw)

Scanning speed 7 m/s, 4,5 m/s for variable focus move

Focus diameter 50 μm, optional variable focus move (50 μm – 500 μm)

Reference clamping system (optional) EROWA, System 3R / others on request

Connected loads Max. power consumption 7.4 kW

Power supply 3/N/PE AC 400 V, 32 A, compressed air 5 bar

Inert gas supply 2 gas connections provided

N2 generator external (optional)

Inert gas consumption < 1 m3/h

Filtering system integrated, with a 20 m2 fi lter surface

Dimensions 2542 x 1818 x 1987 mm3 (W x D x H)

Weight approx. 2.400 kg

Operating conditions 15 – 35°C

LaserCUSING® materials CL 20ES Stainless steel (1.4404)

CL 31AL Aluminium alloy (AlSi10Mg)

CL 41TI ELI Titanium alloy (TiAl64V ELI)

CL 42TI Pure titanium Grade 2

CL 50WS Hot-work steel (1.2709)

CL 91RW Stainless hot-work steel

CL 92RW Precipitation hardening

stainless steel (17-4 PH)

CL 100NB Nickel-based alloy (Inconel 718)

CL 101NB * Nickel-based alloy (Inconel 625) *

CL 110CoCr * Cobalt-chromium alloy (F75) *

remanium® star CL Cobalt-chromium alloy (by Dentaurum)

rematitan® CL Titanium alloy (by Dentaurum)